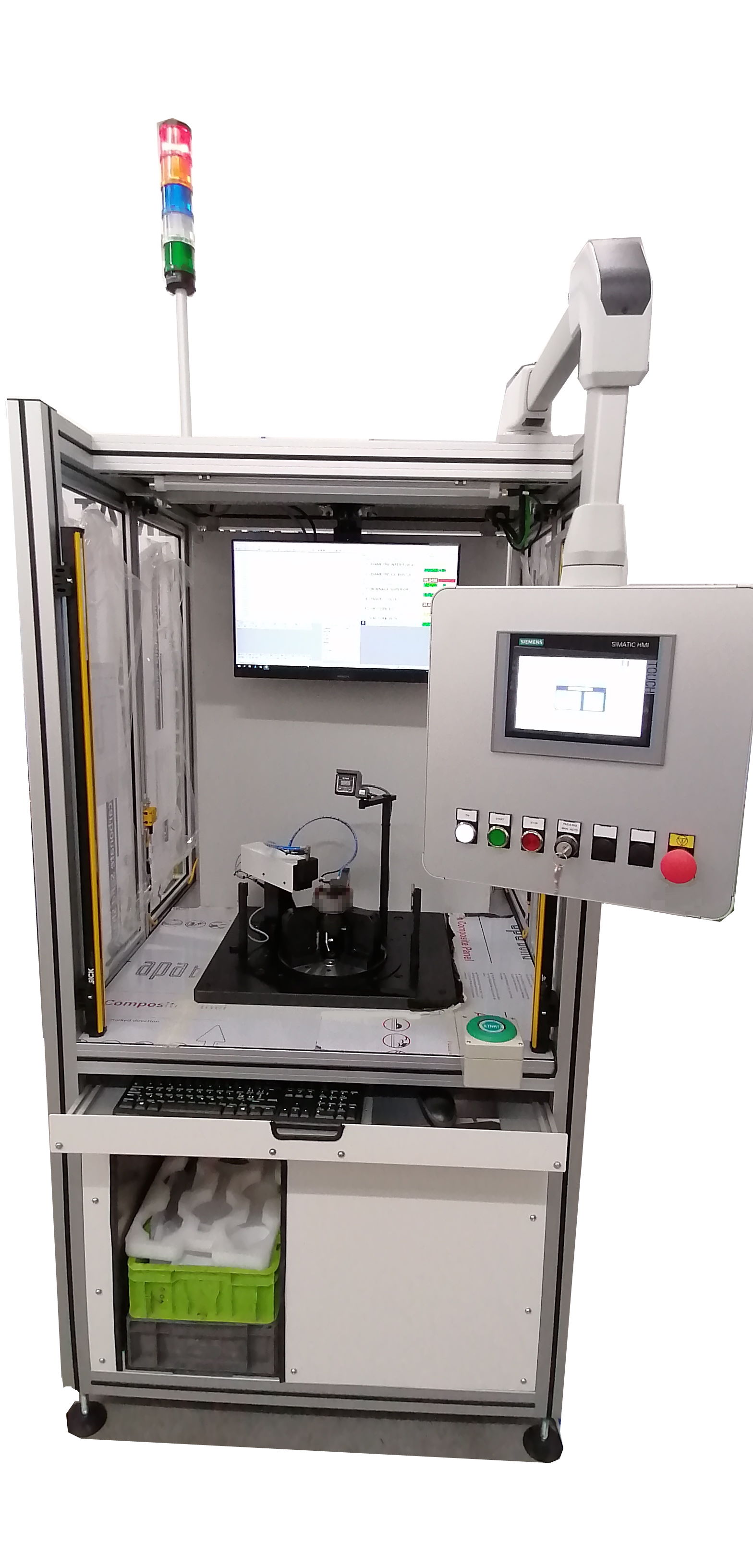

On 05/28/2025, the process for the call for proposals by Lombardy Region was concluded.

Development project for a new plant to be used as a new company headquarters financed by the regional program under the European Regional Development Fund 2021/2027 of Lombardy Region PR FESR 2021-2027.

Action: ACTION 1.3.3 Support for investments in Small and Medium-sized Industries.

Call for proposals: INVESTMENT MEASURE – BUSINESS DEVELOPMENT LINE