|

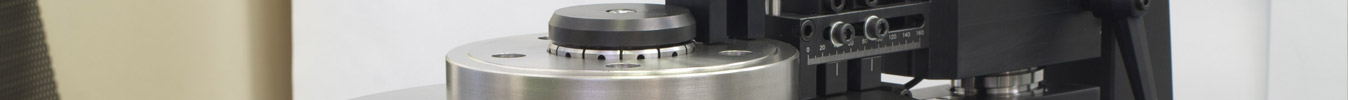

100% dimensional and geometric control of brake discs Itageo6© station in line for the 100% control of brake discs. Automatic management of the cycle of Master Verification and Master Zero Setting. Management of the dialogue with production machines. Connection with marking systems in order to guarantee the traceability. Approximate cycle time: 10 seconds. The station is available in different configurations, according to customer’s requirements. |

|

|

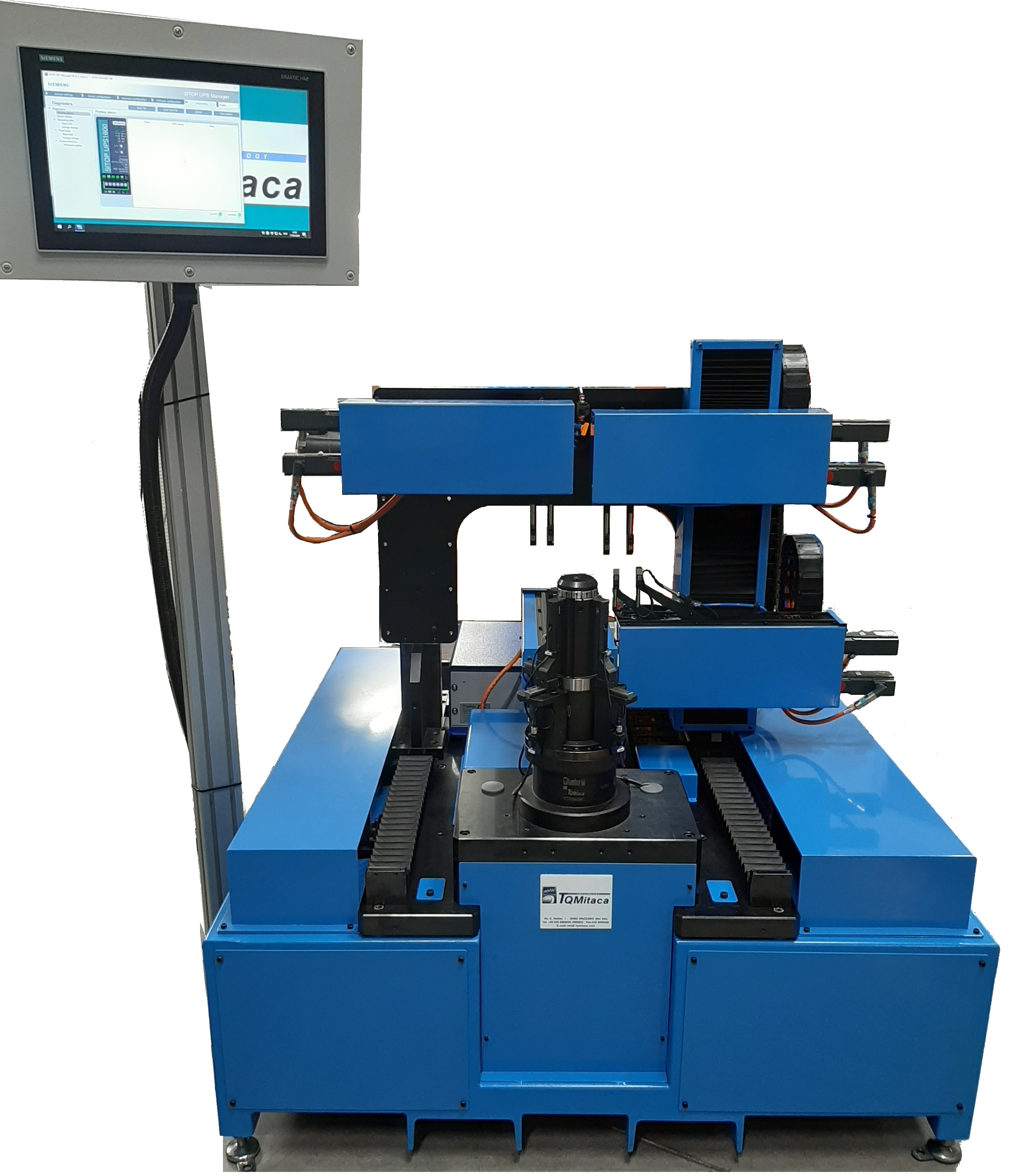

100% dimensional, geometric and FRF control of brake discs Itageo6© station in line for the 100% geometric and FRF control of brake discs. Automatic management of the cycle of Master Verification and Master Zero Setting. Management of the dialogue with production machines. Connection with marking systems in order to guarantee the traceability. FRF control integrated: there is an elevator on which the disc is put by the robot. The elevator puts the disc on the mandrel, dimensional measuring cycle, the disc is released by the mandrel, frequencies cycle, the disc is extracted by the robot. Approximate cycle time: 10 seconds The station is available in different configurations, according to customer’s requirements. |

|

|

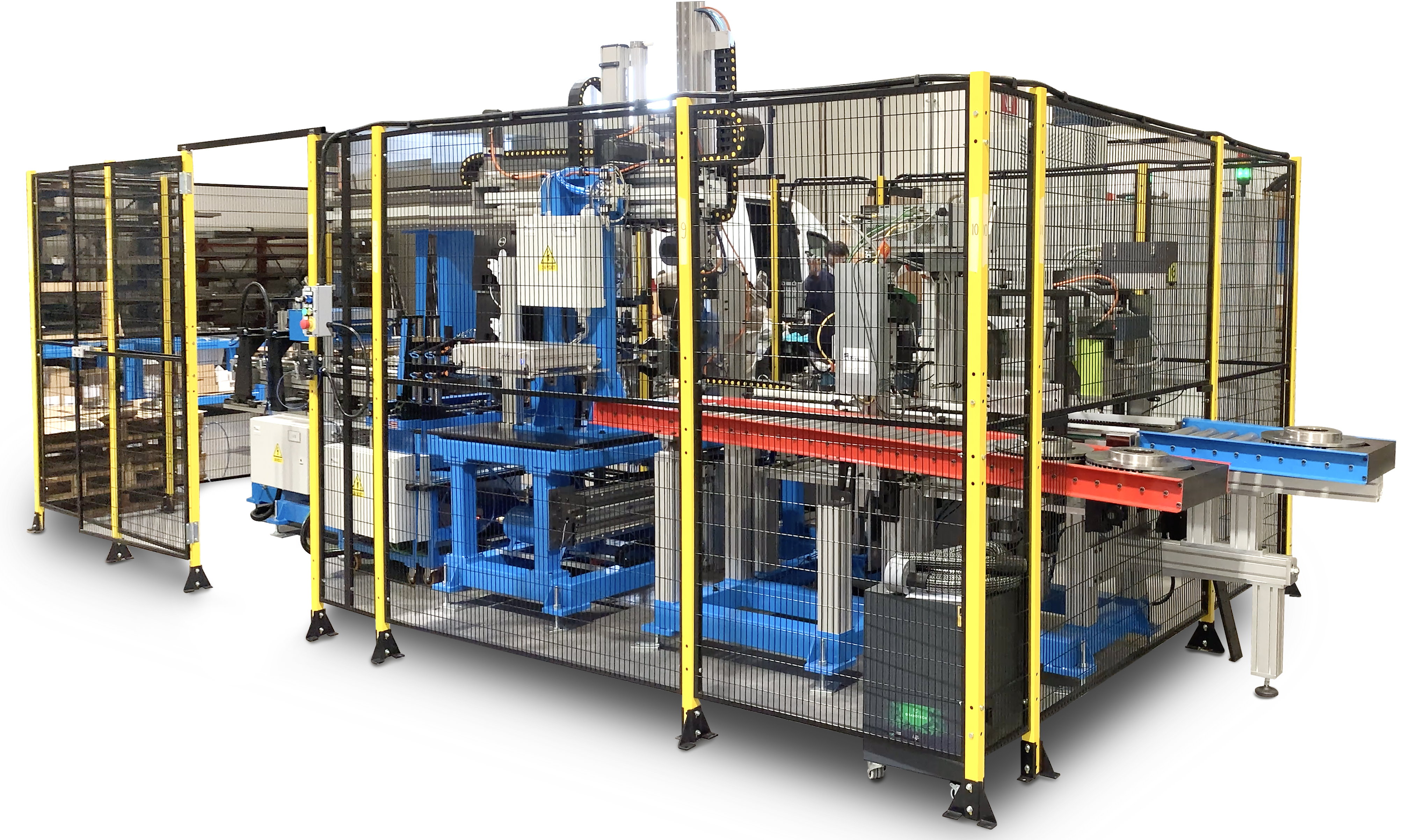

Automatic Retooling measuring stations for Itageo 6© station to be included in lines or island for dimensional and geometrical (and FRF, on request) of 100% Brake Disc production. Integrated FRF control (on request): there is an elevator on which the disc is put by the robot. The elevator puts the disc on the mandrel, dimensional measuring cycle, the disc is released by the mandrel, frequencies cycle, the disc is extracted by the robot. Estimated cycle time: 10 seconds. The station can be customized depending on customer needs |

|

|

Special / Custom Measuring stations for Itageo 6© station for dimensional and geometrical (and FRF, on request) of 100% Brake Disc production. Integrated FRF control (on request): there is an elevator on which the disc is put by the robot. The elevator puts the disc on the mandrel, dimensional measuring cycle, the disc is released by the mandrel, frequencies cycle, the disc is extracted by the robot. Estimated cycle time: 10-15 seconds. The station can be customized depending on customer needs |

|

|

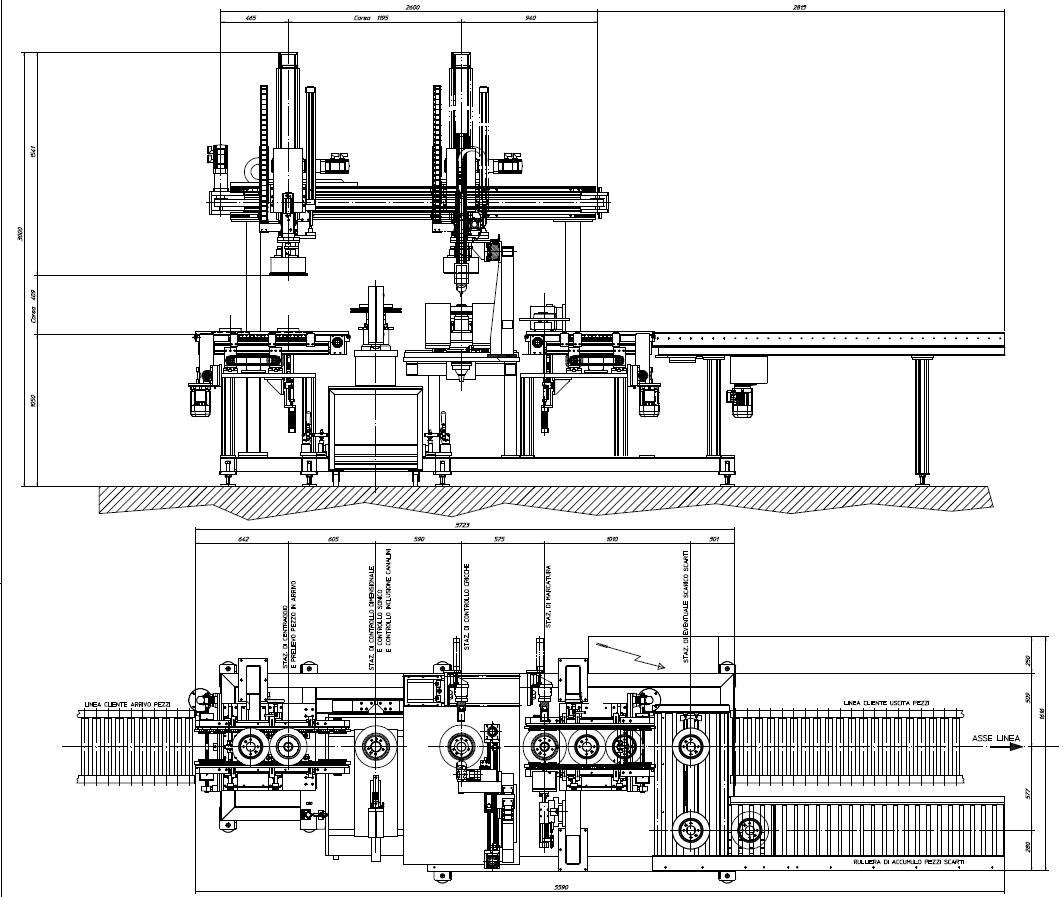

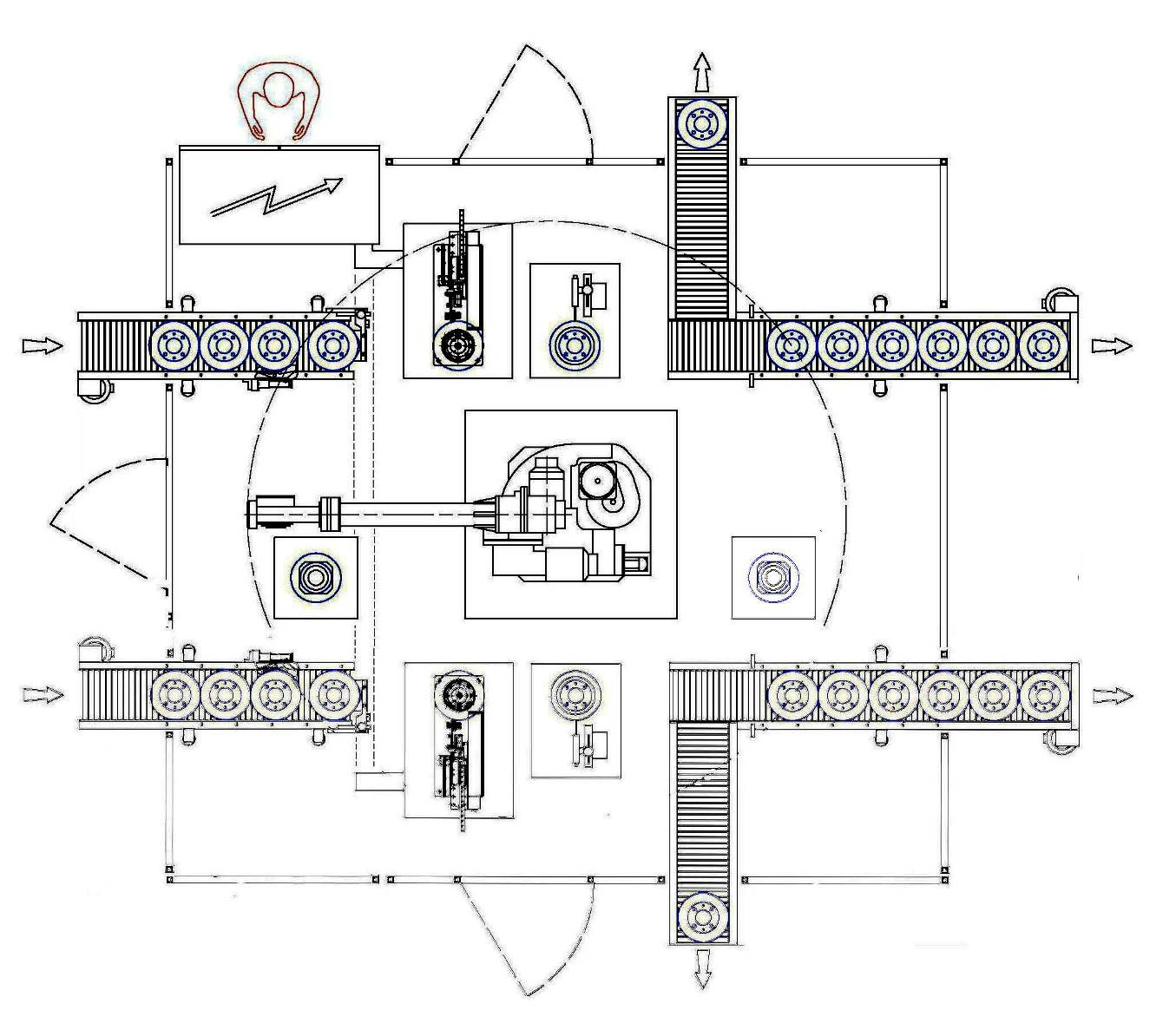

Itageo6© station for the control of brake discs in production line equipped by powered roller conveyor and linear system for the handling of pieces. This solution is studied for the integration in a production line equipped with a roller conveyor. All the dimensions and the positioning of single components can be defined according to customer’s requirements. It’s a extremely flexible modular solution. Thank to this configuration it’s possible to add different stations, like a marking station, the roughness control, cleaning station in entry, the FRF control, cracks detection, True Position control of the holes made by a video camera, marking of the serial number in order to guarantee the traceability at 100%. The addition of supplementary modules doesn’t influence the cycle time because the control time are kept aligned among the different modules. |

|

|

|

|

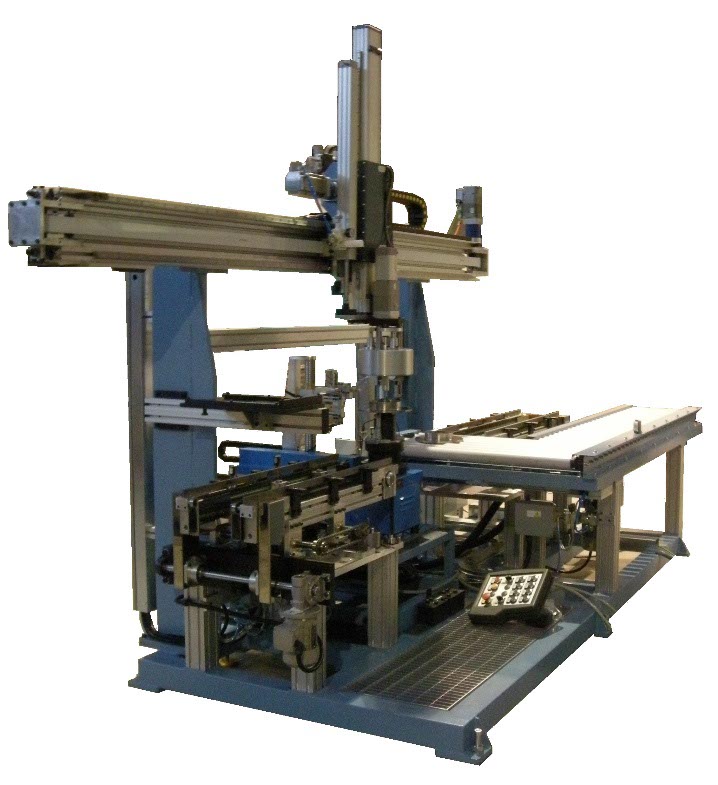

Itageo6© station for the control of brake discs inserted in an automatic line served by an anthropomorphic robot In case of use of an anthropomorphic robot for the movement of the pieces in the isle, it would be easy to integrate the measuring station in the work area. In this case, the system for the control of the discs is composed of an automatic gauge, a marking station and an electrical cabinet containing the PC, PLC and all the others electronic components. The lay-out of the measuring station is defined considering the spaces available in the production line. Normally, the gauge is mounted on a special truck equipped by wheels and a specific fastener device. The electrical cabinet is often put out of the work area. |

|