TQM Itaca Technology srl produces since many years sophisticated control systems for shaft and armatures integrated into the machining lines and constantly aligned to the market requirements.

ITAGEO 6© is the system which allows to do dimensional and geometrical controls in a workshop, on more sections at the same time, with a cycle time of few seconds, and which can obtain results comparable with the results obtained in a metrology room using a laboratory roundness measuring instrument. Itageo 6© is composed of a probe for each section, fixed probes, piece put in rotation, rotation controlled by encoder, recreation of the profile of the section using at least 3.600 points, correct measurement of the interrupted surfaces, harmonics analysis, possibility to apply filters, etc…

Therefore, it can be considered like a “Workshop Roundness Measuring Instrument”.

The stations with ITAGEO 6© are easy to use; they can be integrated in automatic lines, they manage the dialogue with load/unload systems and the corrections to the lathe.

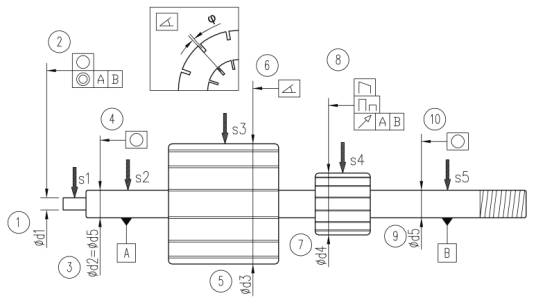

The scheme below shows the characteristics which can be measured with the Itageo gauges:

| 1 | ø d1 – Shaft Pivot Diameter | 5 | |

| 2.1 | Shaft Pivot Roundness | 0,003 | |

| 2.2 | Concentricity d1 A-B | 0,010 | |

| 3 | ø d2 – Shaft Diameter | 8 | |

| 4 | Shaft Roundness | 0,003 | |

| 5 | ø d3 – Stack Diameter | 40 | |

| 6 | Stack Commutator Angle | ±1° | |

| 7 | ø d4 – Commutator Diameter | 18 | |

| 8.1 | Bar Linearity | 0,004 | |

| 8.2 | Commutator bar-to-bar | 0,002 | |

| 8.3 | Oscillation (Run-out) commutator | 0,008 | |

| 9 | ø d5 – Shaft Diameter | 8 |

+ 0,007 + 0,001 |

| 10 | Shaft Roundness | 0,003 | |

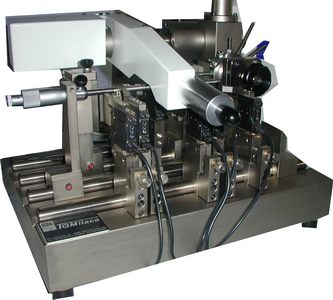

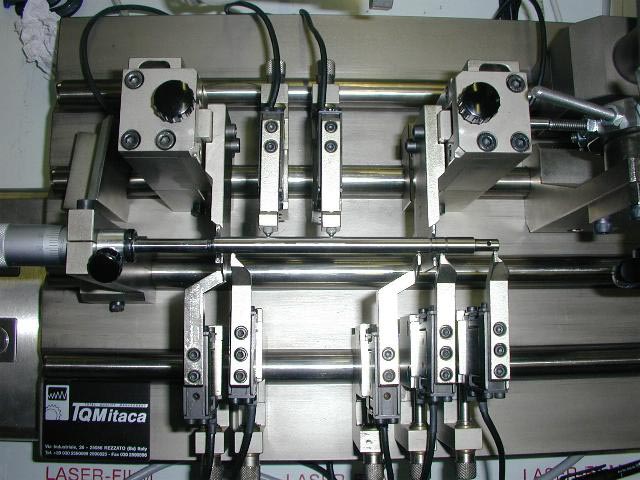

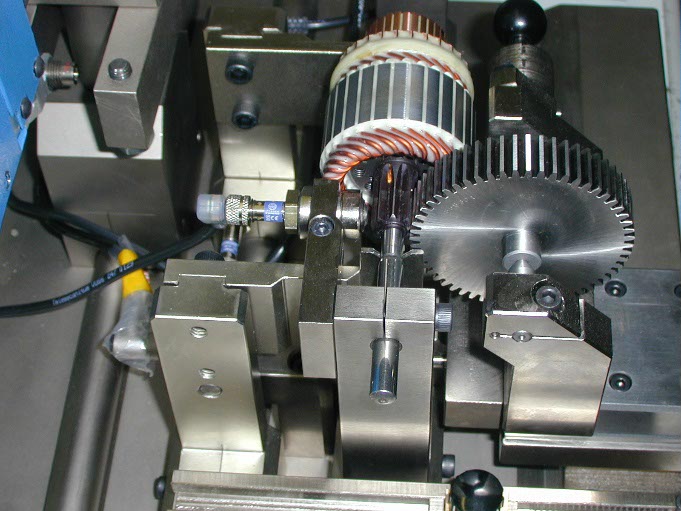

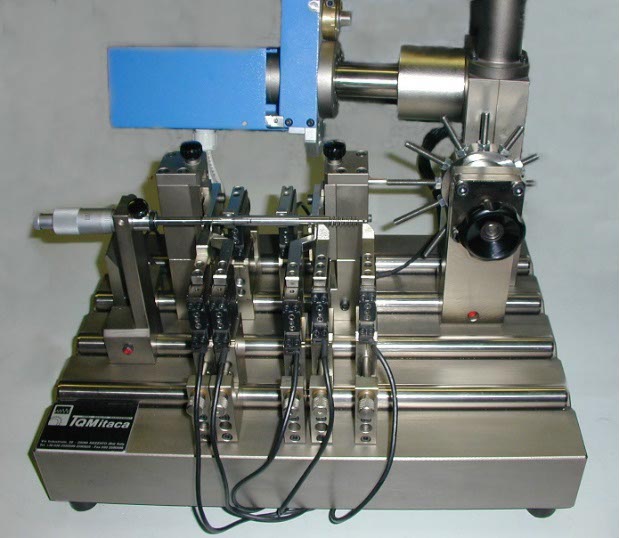

The measuring cycle is automatic also in case of stations with manual load/unload system. The measuring mechanics is completely adjustable, and it’s quite simple because it’s composed of 2 V-supports for the shaft, a feeding group with gear motor and encoder and a totally adjustable support for the probes.

The measuring can be done by electronic contact probes or by non-contact laser probes. The cycle time is about 2-4 seconds, in function of the diameter to be controlled.

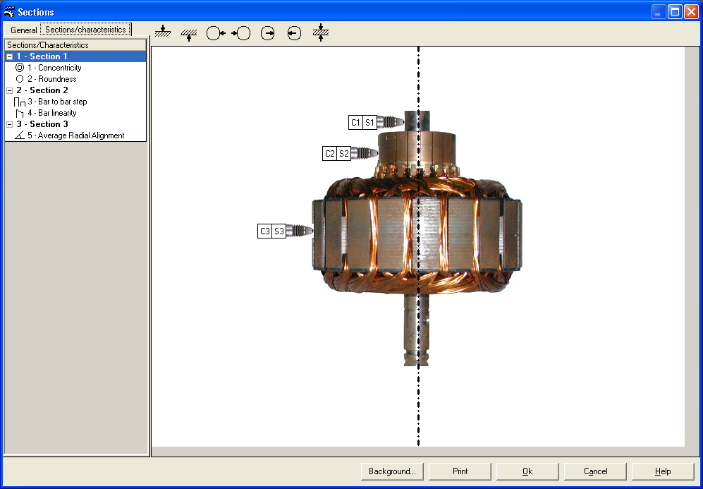

The characteristics to be measured can be relative to a single section (bar to bar, bar linearity, roundness, etc…) or can be a result of a comparison of more sections (Stack-commutator angle, concentricity, etc…).

Itageo 6© envisages an interactive graphic support for the configuration of the tooling and for the realization of the control plans, simplifying its use.

|

|

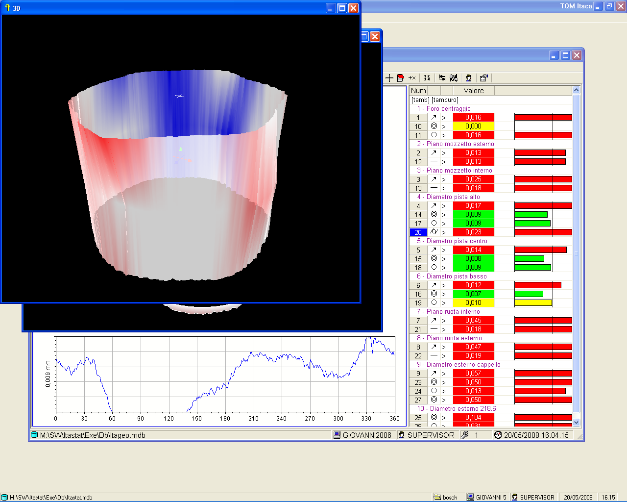

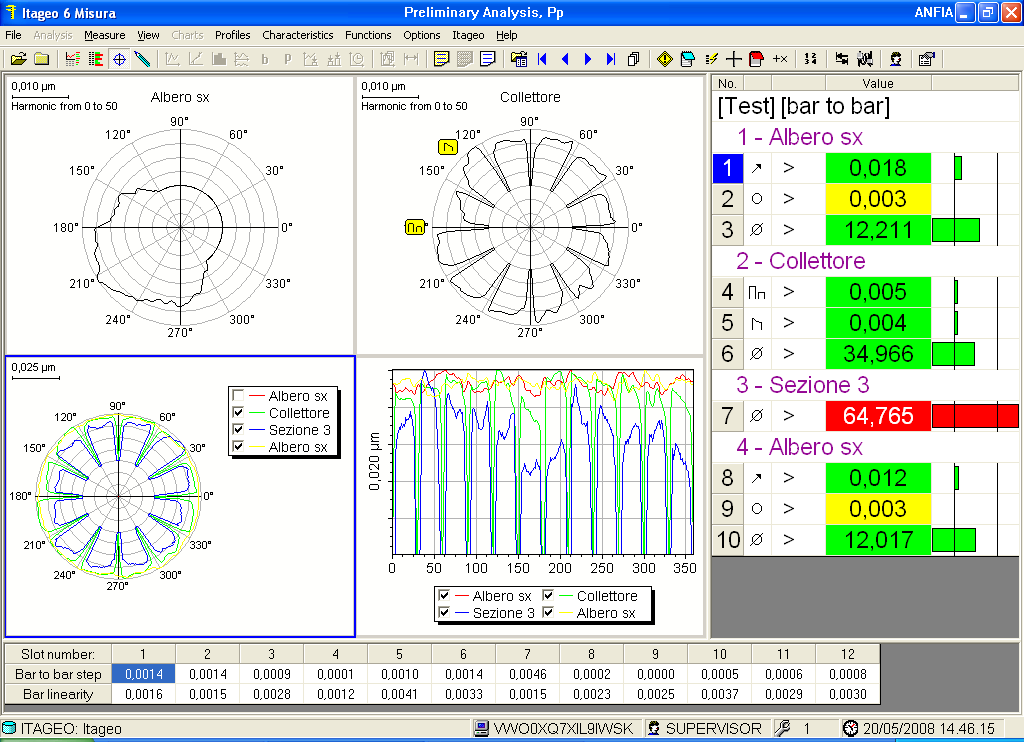

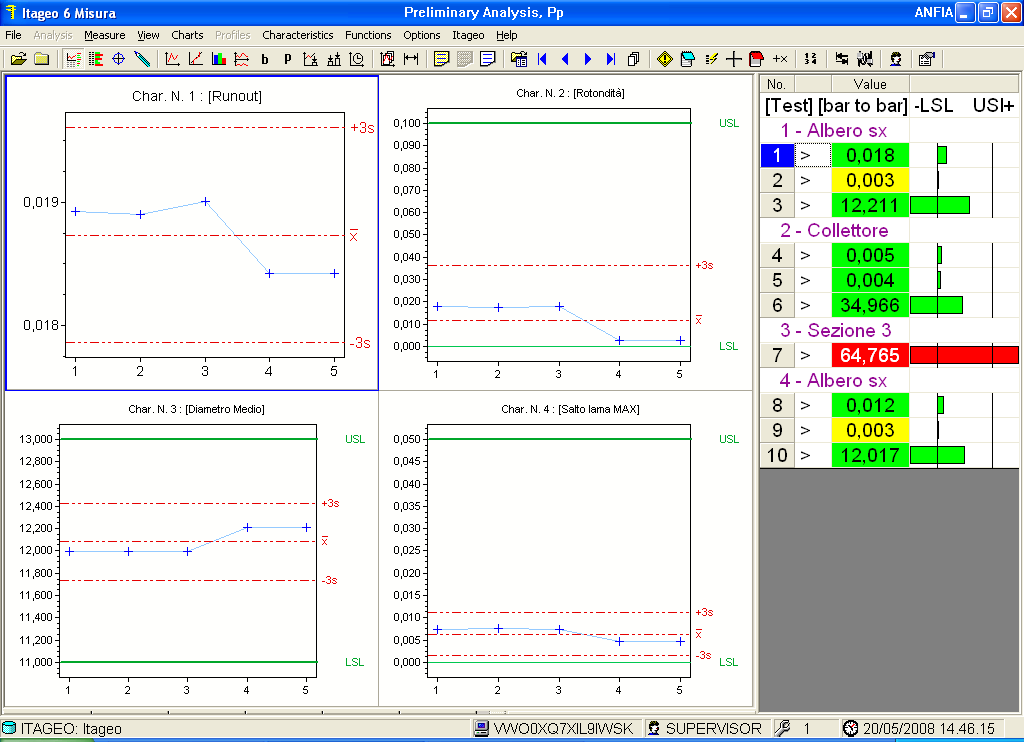

The result of the measuring is displayed as a polar profile and as a linearized graph with possibility of zoom. If necessary, it’s possible to save the graphs of the single tests.

|

|

The results are archived in the database of Itastat and available for statistical analysis.

The version R1 is the solution which allows to control a single section; with the RM version it’s possible the control at the same time of max. 16 sections.

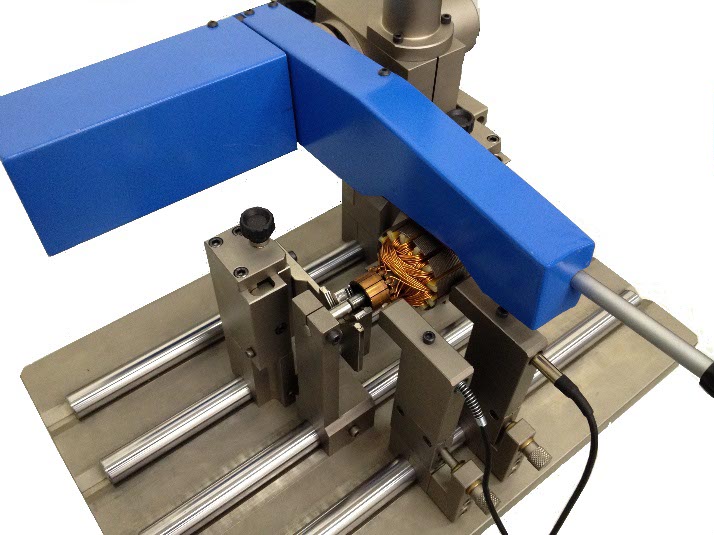

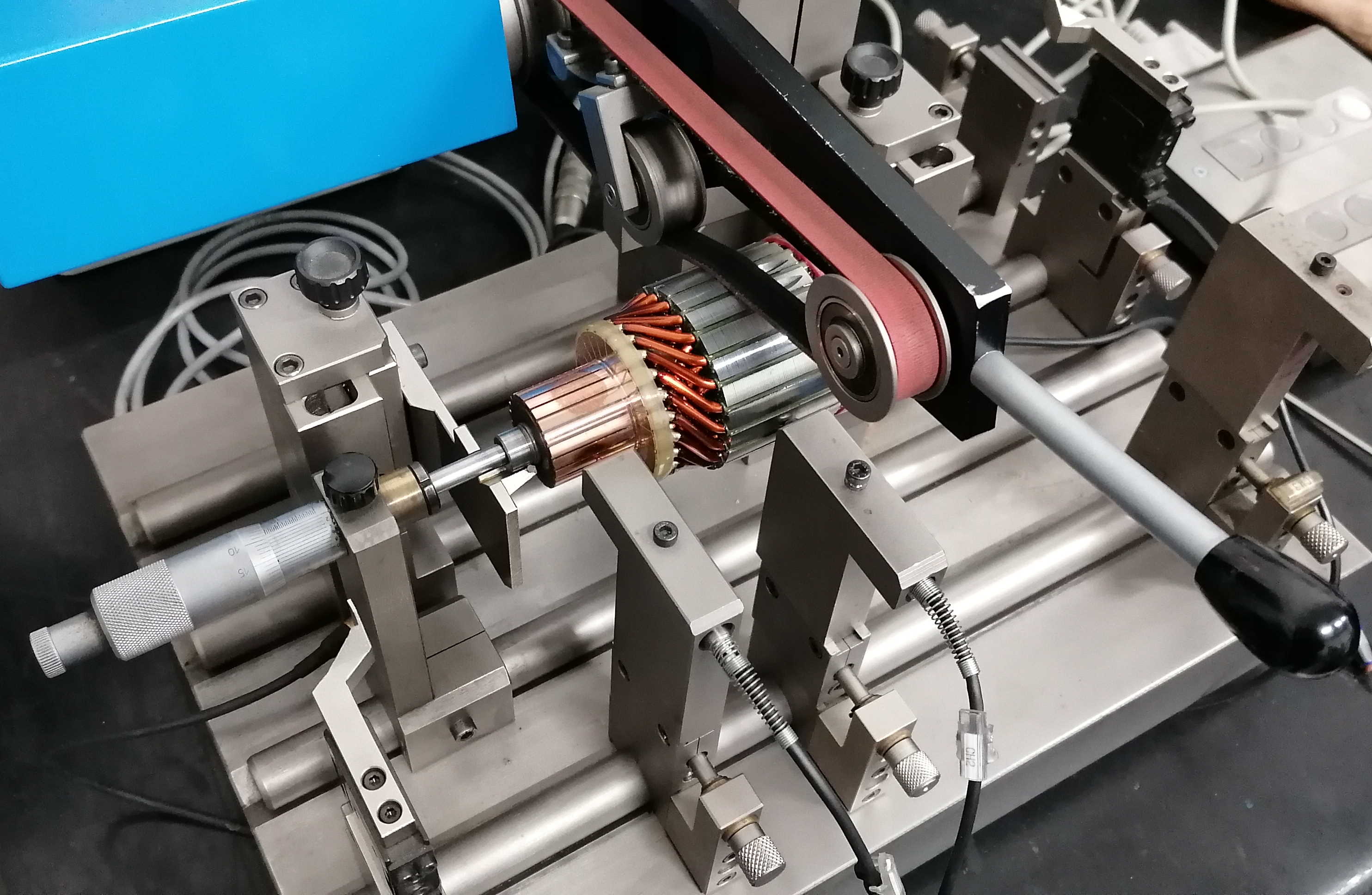

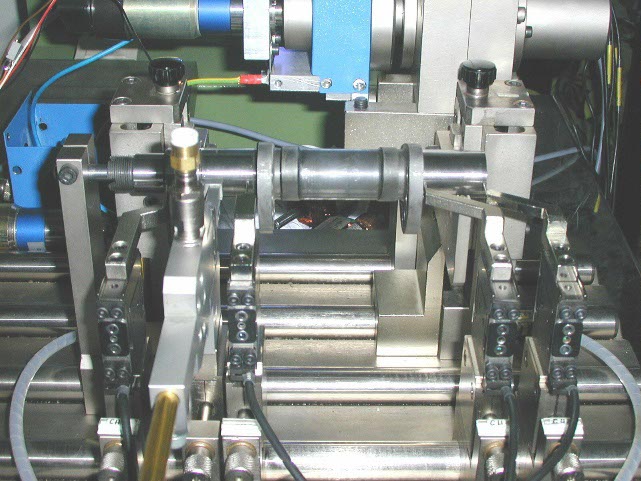

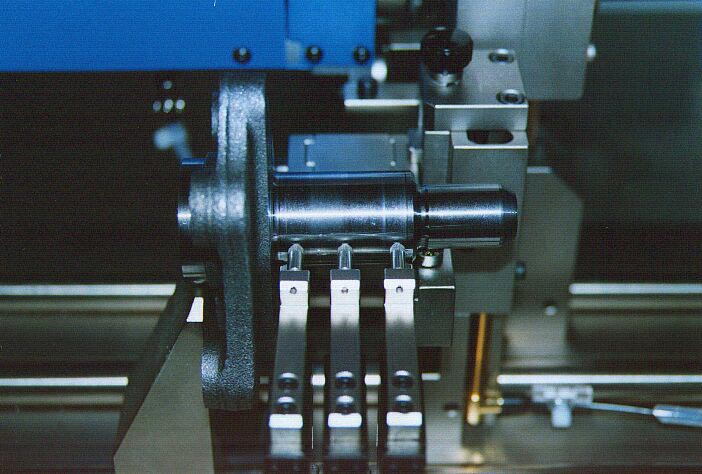

Standard stations for the control of armatures

|

|

|

|

Itageo 6© can be used for the dynamic control of components with different shape and type, using appropriate mechanics; in addition to the known stations for the control of brake discs and brake drums, here below there are some examples of applications with Itageo 6©:

|

|

|

|

|