TQM is involved in the design and creation of analog and digital measurement systems, saving of the gathered data and their use for check, analysis and improvement of the production process and quality management.

For this reason, TQM can be seen as a forerunner in the Industry 4.0 field and IoT (Internet of Things) since its foundation.

Following a process started some years ago, Industry 4.0 is one of the main transformation factors for the economic development in Italy and in the world, and it is recognized as the further step in the Industry revolution.

What is the Industry 4.0 and how this can be implemented in the actual production process?

It is a modernization process that comes from the fourth industrial revolution and it is leading to an automatized and connected industrial production.

These new digital technologies are having a big impact on the following concepts:

- Usage of the data: computing power and connectivity, that is resumed in "big data", "open data", "Internet of Things", "machine-to-machine" and "cloud computing".

- Data analysis: once the data are gathered, they should be used to gave them value.

- Human-machine interaction: through "touch" interfaces and augmented reality;

- Digital-to-real production: additive manufacturing, 3D printing, robotics, communications, machine-to-machine interaction and new technologies to optimize costs and performance.

It is clear that all these activity (with particulr attention for the first ones) can be applied together the measurement systems proposed by TQM Itaca technology.

How TQM can give its contribute to embed the 4.0 systems to the companies?

Today, several analysis show that only the 1% of all data gathered from production is really used from the companies. The companies could obtain big advantages using these data, starting from the so called "machine learning", literally those machines that improve their performances using the data gathered and stored.

Through the TQM software suite Itastat 6 it is possible to measure, store, import, visualize and analyse (also in real-time) a huge quantity of data coming from the measuring system manufactured by TQM itself, or coming from all other possible sources of measure available in a company in the production or laboratory (calibers, gauges, buffers, 3D CMM coordinate measuring machines etc..).

It is possible to share these information to the system in order to actuate the corrective operations on the robotic working centres in real-time, with the aim to stay always in the control limits of the production process.

Quality process control and analysis of the gathered data is nowaday a common practice in situation where an high degree of final product is requested, such as: Automotive, medical, electronics etc..

Neverteless, all these concepts can be applicable to all the production areas, with a gradual process of implementation in today's production, in order to increase the quality level, with savings in terms of money and resources.

The "Company 4.0" (born from the Fourth industrial revolution) it is composed by all new machines connected together, that share data, perform auto-diagnostic and preventive maintenance.

TQM Itaca Technology place itself in this scenario with the ability to provide flexibility to the measurement systems becuase they are being interconnected and re-tooled automatically depending on the specific code of product in the process at that moment.

It will be possible to provide customized products depending on the single customer, with higher flexibility respect the traditional production.

Especially for the automatic retooling measuring systems, the change of product code in the production line can be done in a very short time and without operator intervention, with cost savings and safety improvements.

Theoretically, it could be possible to swap between different codes also for producing one single piece in the same production line.

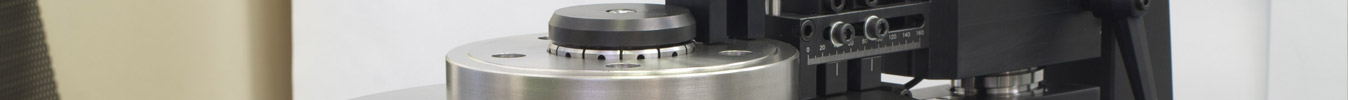

For brake disc production, for example, it is possible to perform the analysis of parts with different geometries and size, automatically adapting the position of the measurement probes on the machine between every measure procedure.

In this way, the production become "smart" and with the measurement systems provide by TQM Itaca Technology, it is possible to obtain clear and coparable results directly from the workshop production.

Image courtesy by vectorpouch / Freepik