Itasonic 2010© utilises the Sonic Resonance method for non destructive controls on raw or processed metallic, ceramic or sintered parts.

Itasonic 2010© is used:

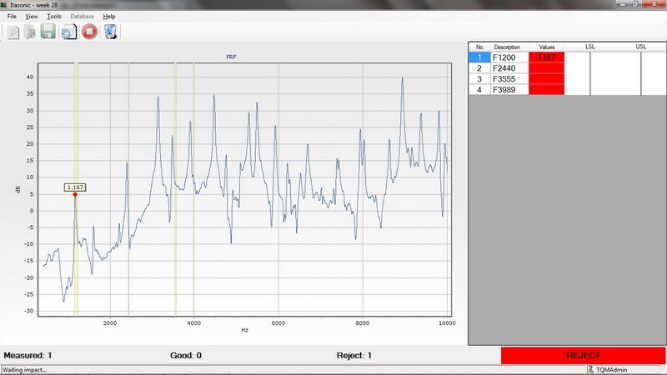

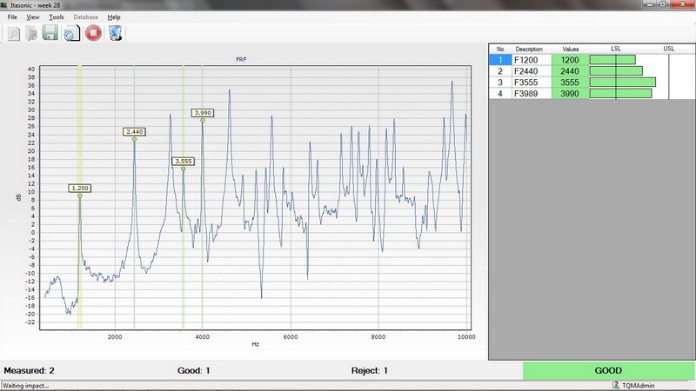

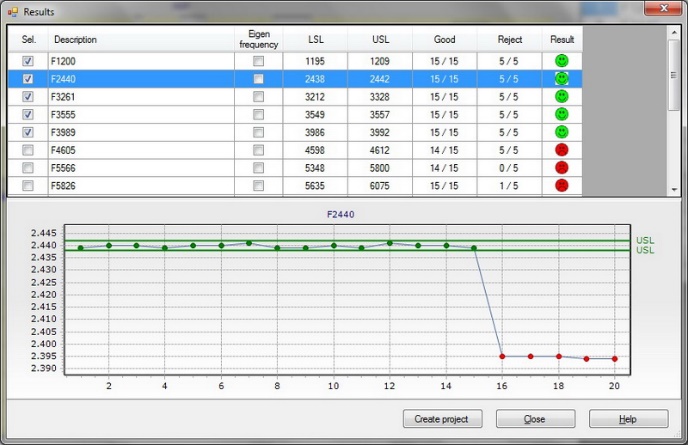

• To test the natural vibration frequencies, a requirement which has become fundamental for components in vehicle braking systems (FRF Analysis).

• To find structural defects such as variation of shape and weight, presence of cracks, stress cracks, discontinuity, density difference and elasticity module.

Sonic control is based on a precise principle of physics: every type of part has its own resonance frequency which generates a unique characteristic curve. In fact, the resonance frequencies depend on clearly defined factors:

• Weight

• Structure

• Form

• Integrity

• Chemical composition

• Mechanical characteristics

The resonance curve will change in presence of variations to the above listed parameters.

The analysis of the resonance frequencies allows to separate in a very short time (1-2 sec.) the good pieces from the rejects.

Itasonic 2010© is available in manual version or in automatic version, and it can be easily inserted in existing production lines.