Complete stations for FRF control

Beyond the supply of manual or automatic equipment to be inserted in existing lines, it's possible to realize stations complete with mechanics, for an automatic use, ready to be inserted in processing isles, for special products, etc...

Here below some examples:

|

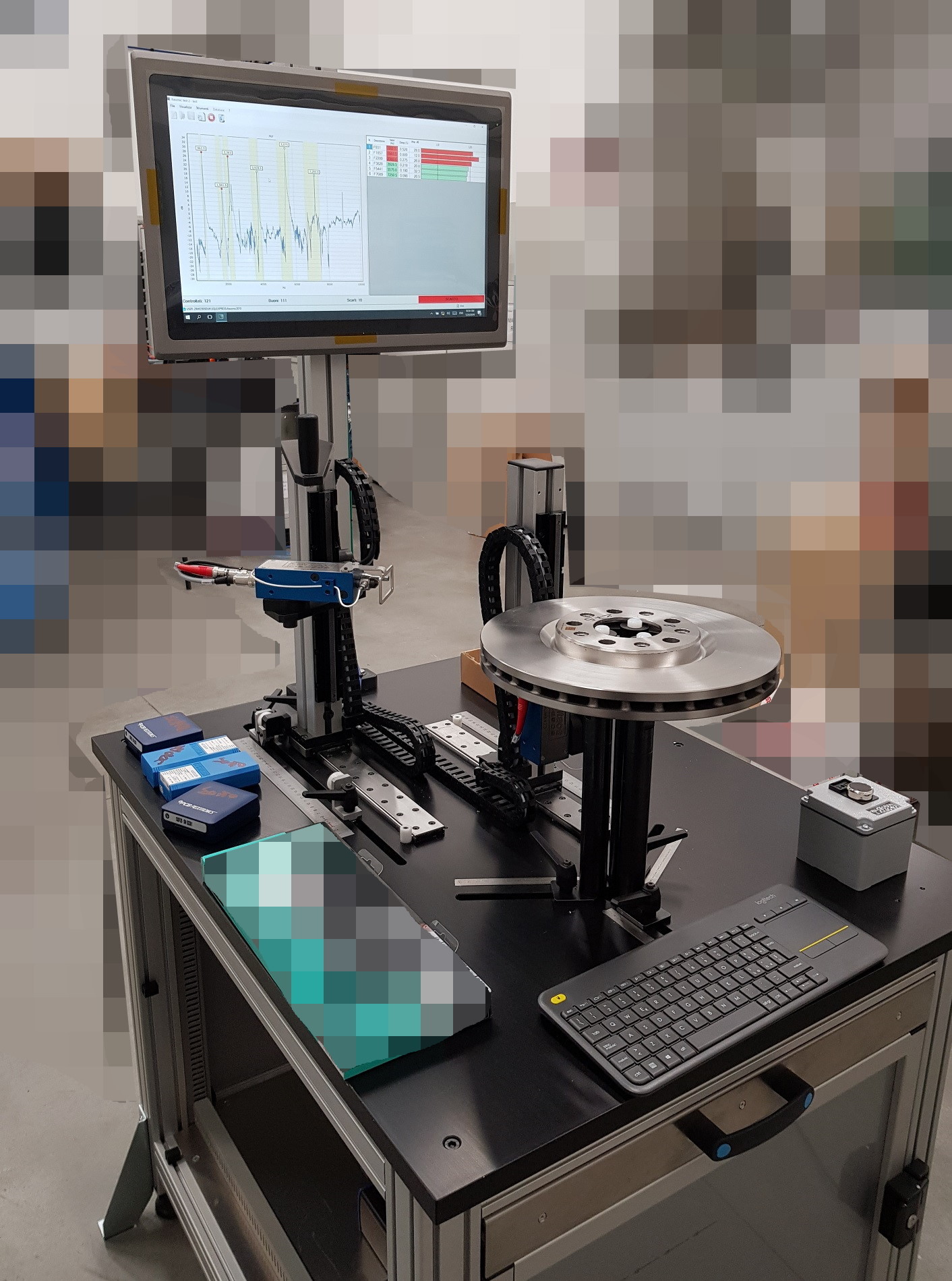

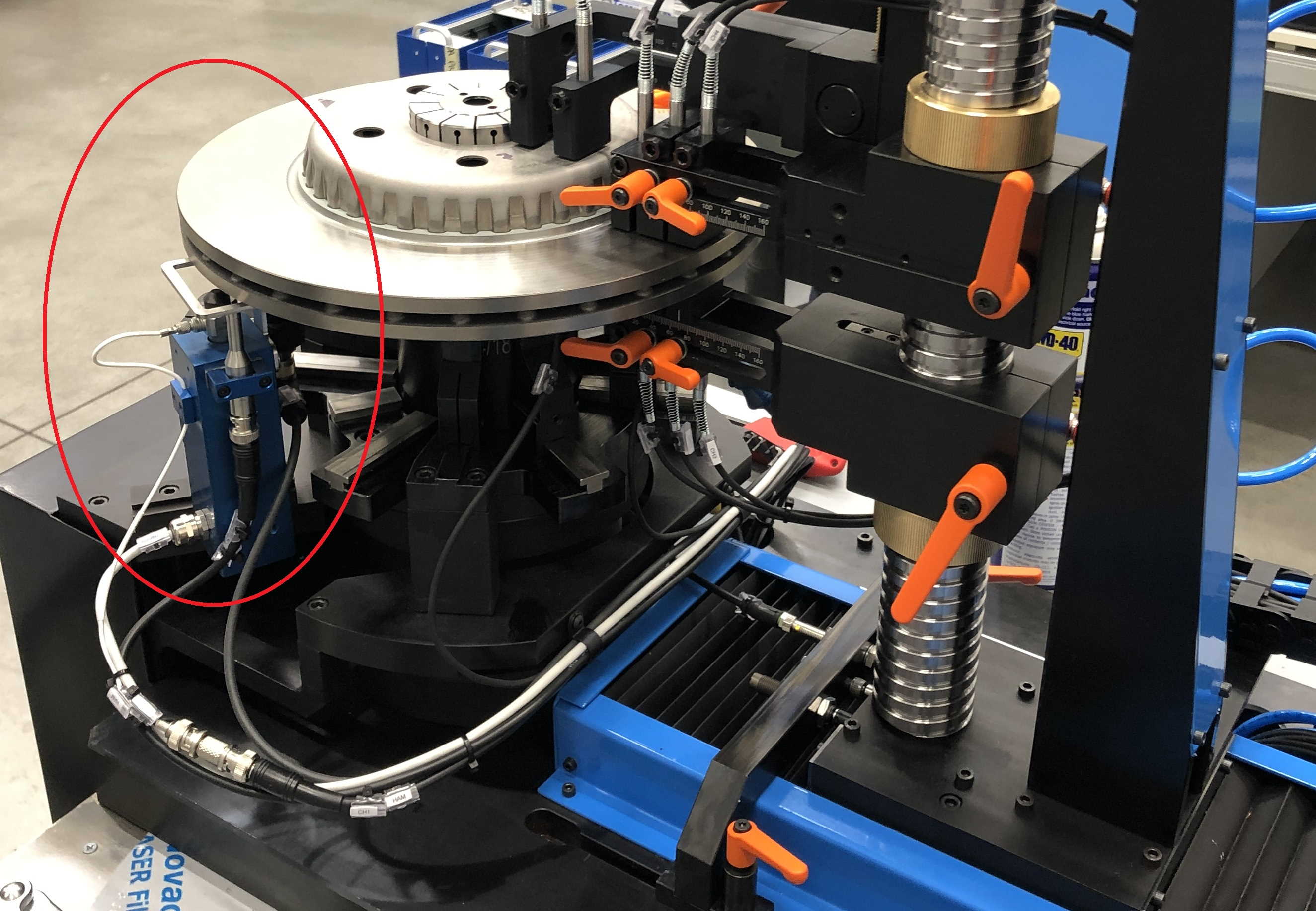

Semi-automatic compact station, for the control of brake discs and brake drums, with adjustable mechanics and integrated electronics, manual load/unload and automatic measuring cycle. |

|

Semi-automatic compact station, for the control of brake discs and brake drums, with adjustable mechanics and integrated electronics, manual load/unload and automatic measuring cycle. Touchscreen operator panel for easy-use configuration. |

|

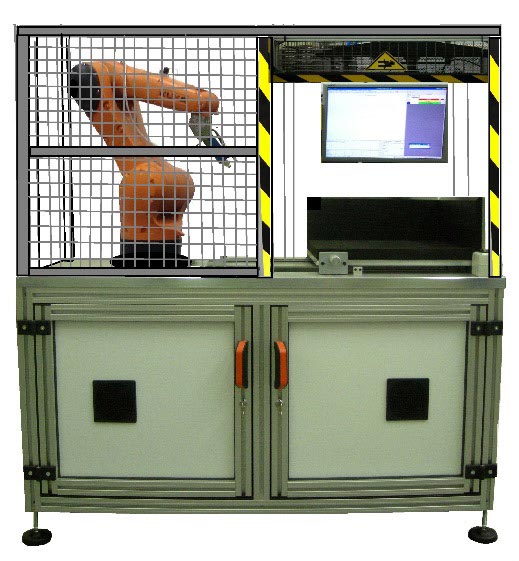

Automatic station for the control of brake discs and brake drums, with adjustable mechanics and the electronics in an electrical cabinet. The load and the unload is made by a robot and the measuring cycle is automatic. |

|

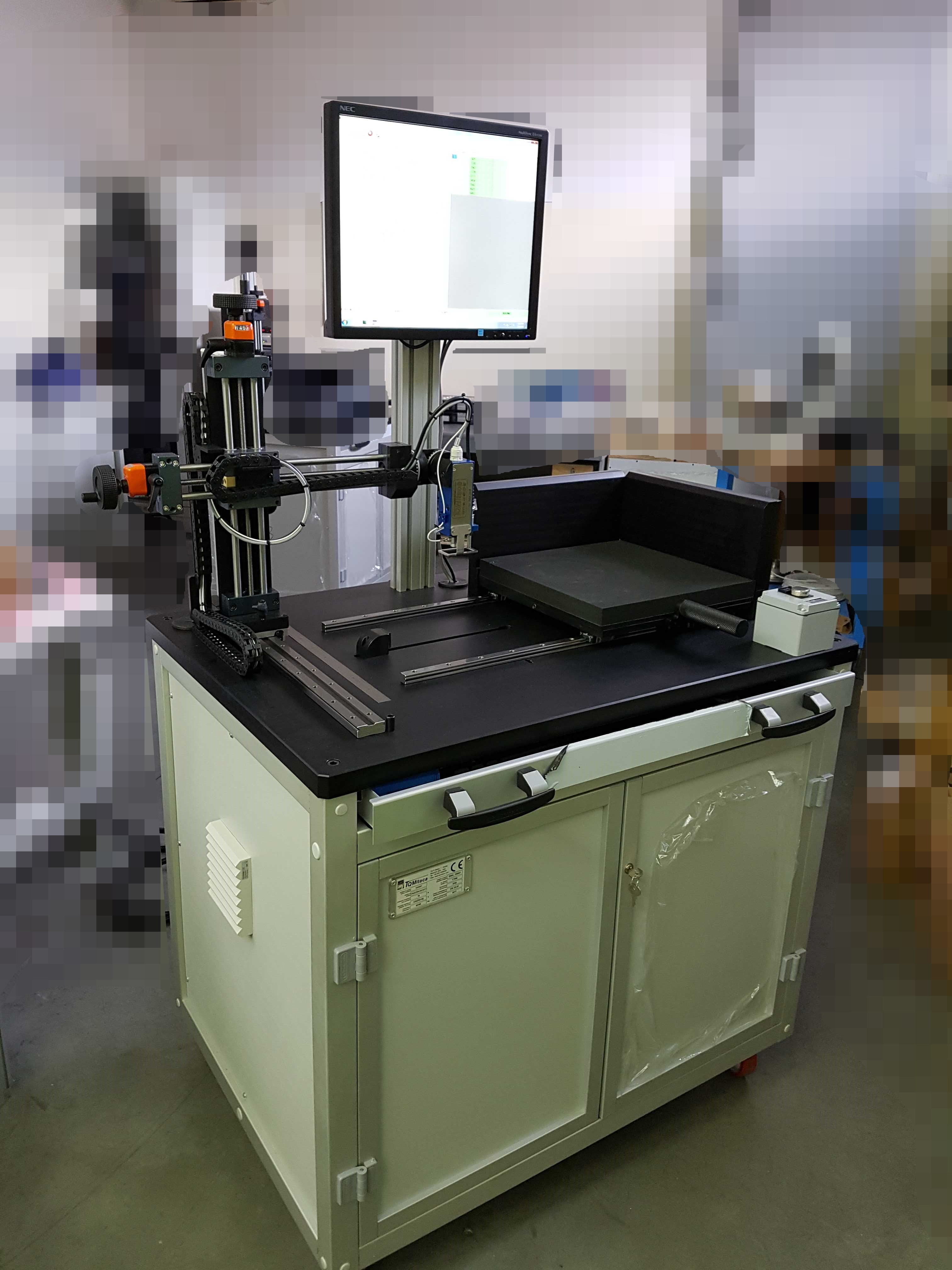

Semi-automatic bench for the control of pliers, brackets, supports, backplates, etc... with an innovative configuration system which guarantees an extreme repeatability of the test conditions: it's the ideal solution to test objects with a complex shape for which it's necessary to hit the part according to the specifications. Manual load/unload. |

|

Automatic bench for the control of pliers, brackets, supports, backplates, etc... with an innovative configuration system which guarantees an extreme repeatability of the test conditions: it's the ideal solution to test objects with a complex shape for which it's necessary to hit the part according to the specifications. |

|

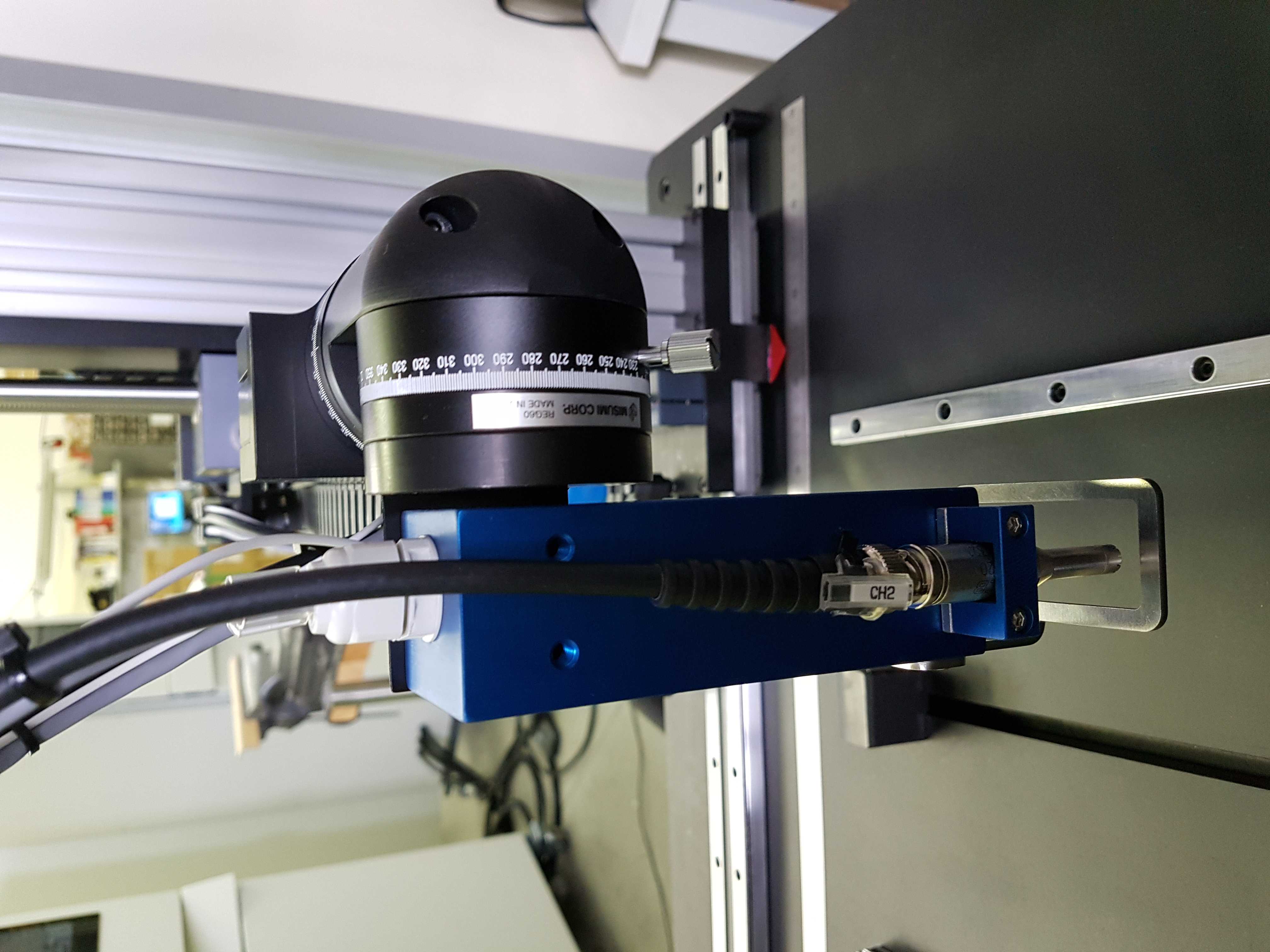

Semi-automatic bench for the control of brake pads for which it's necessary a precise impact point and a precise collocation of the microphone. |

|

|

|

Itasonic 2010© station for the FRF control integrated in Itageo 6© bench for the dimensional and geometric control of brake discs. One only support plane and one only PC: the two software Itageo 6© and Itasonic 2010© work in parallel, the result of the control depends on the two cycles. It's possible to manage separate outputs from the robot according to the type of out of tolerance (frequencies or dimensional). Automatic load/unload, cycle time of about 10 seconds. |

|