ITAGEO 6© is the system which allows to do dimensional and geometrical controls in a workshop, on more sections at the same time, with a cycle time of few seconds, and which can obtain results comparable with the results obtained in a metrology room using a laboratory roundness measuring instrument. Itageo 6© is composed of a probe for each section, fixed probes, piece put in rotation, rotation controlled by encoder, recreation of the profile of the section using at least 3.600 points, correct measurement of the interrupted surfaces, harmonics analysis, possibility to apply filters, etc…

Therefore, it can be considered like a “Workshop Roundness Measuring Instrument”.

The control of the roundness and of the flatness with the traditional control methods doesn’t allow to obtain, if not in particular cases, results comparable with those obtained using a roundness measuring instrument (Talyrond or equivalent) in a laboratory. In fact, with the traditional method it’s possible to measure with 2 probes in differential (a+b) the diametral variation indicating as roundness the difference max-min. The roundness measuring instrument uses a unique probe and it indicates as roundness the radial difference between the inscribed circumference and the circumscribed circumference, after having annulled the eventual error of concentricity. The consequence of this is that with the traditional method it’s possible to have acceptable measures only for errors with a number of lobes equal (oval, square, etc…) but not for a errors with a number of odd lobes (triangle, pentagon, etc…). It’s possible to use three probes at 120° for the triangularity, but in this mode it’s not possible to read correctly the ovality, and furthermore the measuring mechanics becomes very complicated.

ITAGEO 6©, our special program for the dimensional and geometric controls, allows to obtain in a workshop results comparable with the results obtained by a roundness measuring instrument because it uses the same measuring method:

• Use of a single probe for each section

• Acquisition of a number of adjustable points for each section (typically 4.000)

• Calculation of the eccentricity with re-centring of the profile

• Calculation of the roundness on the re-centered profile

• Display of the polar and linear profile

With ITAGEO 6© it’s possible to set the function “harmonic filter”, like the roundness measuring instruments, the search of the harmonic of higher order (it’s possible to calculate the amplitude of the harmonics according to the Fourier Analysis), the setting of different tolerances for each harmonic, etc…

ITAGEO 6© is able to compensate the measuring errors due to the rotation on “V”, both on the support plane and on the other controlled sections, evaluating the form error in the correct way (2 lobes, 3 lobes, etc…).

ITAGEO 6© allows to analyse up to 16 sections at the same time. The surfaces can be continuous or interrupted.

Repeatability for 25 measures on a master

Indicative values of 6 sigma:

| Roundness | < | 0,6 | µm |

| Bar-to-Bar | < | 0,3 | µm |

| Average Diameter | < | 0,3 | µm |

|

Planarity (lathed piece, filter 50Hz) |

< | 1 | µm |

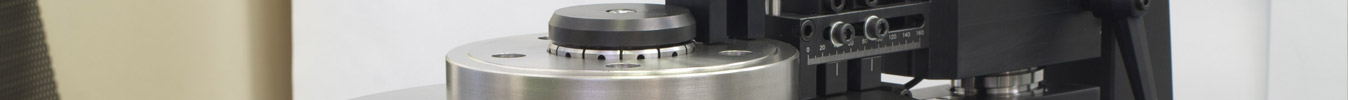

ITAGEO 6© is the instruments for dimensional and geometric controls in workshop for brake discs and brake drums. It allows to obtain, in a workshop, with 100% control, results comparable to the results obtained using a laboratory roundness measuring instrument. It can be automatic or semi-automatic (automatic measuring cycle and manual load/unload of the piece). This result is possible because ITAGEO 6© uses the same measuring logic of a roundness measuring instrument:

• Piece put in rotation on a precision mandrel.

• Compensation of the errors of rotation induced by the mandrel.

• Use of a contact probe for each section.

• Reconstruction of the profiles, Fourier Analysis and Harmonic Analysis, Calculation of the eccentricities and of the roundnesses on the re-centered profile.

• Display of the polar and linear profile.

Moreover, ITAGEO 6© has some characteristics which make it appropriate for a use in a workshop:

• Extremely sturdy mechanics, electrical cabinet with adequate protections, industrial electronics.

• Adjustable gauges with fast and simple operations.

• Simple use, suitable for the line staff.

• Completely automatic measuring cycle, also in the version with manual load/unload.

• Itageo is able to manage the dialogue with manipulators, lathes, marking machines, machines for the “Eigen Frequencies” control, stations for ND control.

• Cycle time of about 15 seconds, load/unload included, with discs of standard dimensions.

• Management of more probes at the same time (up to 16 probes): the control plan can be more complex without influencing the cycle time.

• DTV measurement with a tolerance of 5 micron.

• Measurement of interrupted surfaces, with the exclusion of the holes for the analysis.

• Adjustable automatic management of Master Verification and Master Zeroing, with the control of the stability of the gauge.

• Possibility to set the “harmonic filter”, analogue to the filter which is present on the roundness measuring instruments, search of the harmonic of a higher order (harmonics of order 2°,3° ,4° and 5° according to Fourier Analysis), possibility to set the “dirty filter”.