Itageo 6© is optimized for the dynamical controls and allows to control diameters with a single probe for each section. The result is the simplicity of the mechanical configuration and type change.

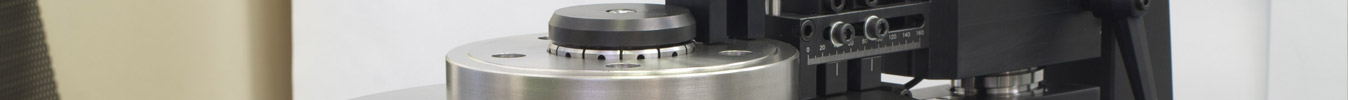

To guarantee the highest precision and reliability of the measurement, Itageo 6© works on the same measurement principles as laboratory roundness measuring instruments: a piece is put on rotation on a precision mandrel, angular control via encoder, a contact probe on each section to be measured, acquisition of at least 7.200 points/rotation for each analysed section, reconstruction and analysis of the obtained profile.

The analysis of the profiles allows:

• Visualization in real time of real profiles, big help in order to individuate possible causes of technical problems due to the production of the same pieces.

• Fourier Analysis, with decomposition of the form errors in single components, with the possibility of manage different tolerances for each error.

• Possibility to implement filters.

• Possibility to implement dirty filter.

• Possibility to analyse for sections of circumference: ex. Roundness each 30°.

• Possibility to compensate the rotation errors generated by the mandrel.